If you’re a car enthusiast in Central New York, you know the struggle: years of road grime, oxidation, and “Syracuse salt” can turn even the most legendary engine into a dull, corroded mess.

At Cantech Automotive, we don’t just “wash” parts. We restore them. Whether you’re mid-restoration on a vintage Porsche or just want your daily driver’s engine bay to pop, our Vapor Blasting service is the ultimate “reset button” for metal.

Why the Cantech Team Chose Vapor Blasting

Most shops rely on dry sandblasting, which hits metal with sheer force. While that’s fine for heavy-duty frames, it’s far too aggressive for the precision components we handle daily at our Syracuse facility.

We invested in the Vixen AquaBlast system because it treats your parts with the respect they deserve. By using a pressurized water slurry mixed with fine abrasive media, we aren’t just blasting, we’re honing.

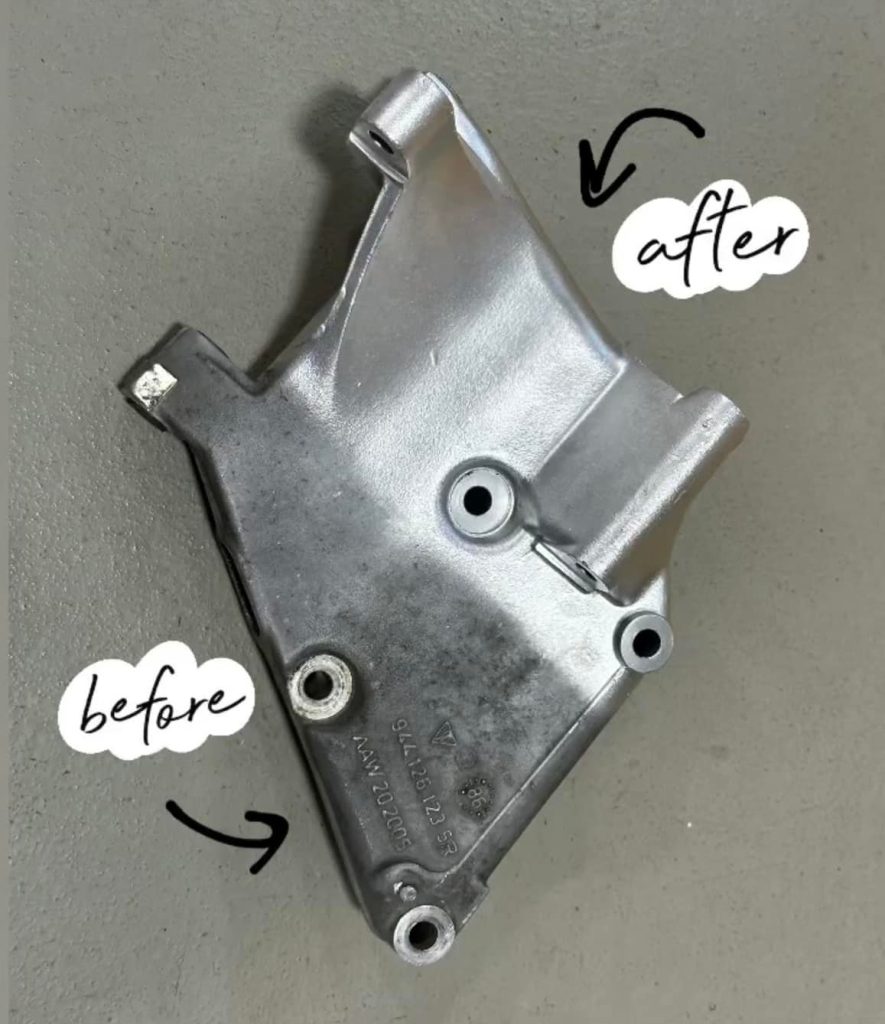

The Difference You Can See (and Feel)

Why does a vapor-blasted part from Cantech look so much better than one that’s been sandblasted? It comes down to the science of the “Flow”:

No Surface Damage: The water acts as a hydraulic cushion. It scrubs the grime away without digging into or warping the metal.

The “Satin” Secret: Instead of a rough, jagged surface, vapor blasting leaves a smooth, peened finish that actually resists future dirt and fingerprints.

Deep Cleaning: Because it’s a liquid process, the slurry flows into the tiny nooks and crannies of complex engine castings that dry media simply can’t reach.

What Parts Should You Bring to Our Syracuse Shop?

Vapor blasting is the gold standard for non-ferrous metals. If you have aluminum, brass, or copper parts that look tired, we can bring them back to life. Our team regularly handles:

Engine Components: Cylinder heads, intake manifolds, and timing covers.

Suspension & Chassis: Control arms, brake calipers, and hubs.

Transmission Cases: Getting that “fresh out of the box” look for gearboxes.

The Porsche Project: A Cantech Real-World Result We recently had a Porsche intake manifold in the shop that was completely caked in decades of oxidation. After a session in the AquaBlast, it didn’t just look “clean” it looked like it had just been cast at the factory. This is the level of detail we provide for every client, from Syracuse weekend warriors to serious collectors.

Ready to Restore?

Don’t settle for “clean enough.” If you’re in the Syracuse area and want to see your parts restored to a better-than-new finish, come talk to the specialists at Cantech Automotive.

Whether it’s a single wheel or a complete engine rebuild, we have the tools and the expertise to handle your high-value components with care.

Stop by our shop or contact us today to get a quote for your restoration project!

Vapor Blasting: Frequently Asked Questions

What is the difference between vapor blasting and sandblasting?

While traditional sandblasting uses dry media and high pressure to strip surfaces, vapor blasting (wet blasting) uses a water-based slurry. The water cushions the impact, protecting the underlying metal and preventing the “pitting” or warping often caused by dry blasting. This makes it much safer for delicate automotive components like engine blocks and carburetors.

What materials are best suited for vapor blasting?

Vapor blasting is ideal for non-ferrous metals. We most commonly use it to restore aluminum, magnesium, copper, brass, and bronze. It is the gold standard for restoring aluminum engine casings and intake manifolds to their original factory luster.

Do I need to disassemble my parts before bringing them to Cantech?

Yes. For the best results and to ensure your components are cleaned thoroughly, all parts should be fully disassembled. Bearings, seals, and gaskets should be removed. If you aren’t sure how to prep your part, give our Syracuse shop a call—we can help guide you through the process.

Can vapor blasting remove heavy rust?

Vapor blasting is a finishing process rather than a heavy-duty stripping process. While it is excellent at removing oxidation and light corrosion, extremely heavy scale or rust may require a different approach first. Our team can evaluate your parts and recommend the best restoration path.

Will my parts rust after vapor blasting?

Since vapor blasting leaves the metal “pores” open and clean, ferrous metals (like steel) can flash-rust if not treated. However, for the aluminum and brass parts we typically blast, the process leaves a smooth, peened finish that is actually more resistant to dirt and grease than a raw, dry-blasted surface.

How much does vapor blasting cost in Syracuse?

Pricing depends on the size and complexity of the part, as well as the level of cleaning required. Because we are a specialized automotive facility, we provide custom quotes for every project. Contact Cantech Automotive today for an estimate on your restoration project.